Industrial Automation – What Is Worth Knowing About It?

Industrial automation is one of the most important drivers of modern manufacturing. By combining machines, control systems, and digital technologies, it helps companies increase efficiency, improve quality, and reduce costs.

What Is Industrial Automation?

Industrial automation means using machines, robotics, sensors, and software systems to perform production processes with minimal human intervention. Instead of relying on manual work, automation ensures tasks are performed faster, more accurately, and with greater consistency.

Key Components

-

Robotics: Used for welding, assembly, painting, and packaging.

-

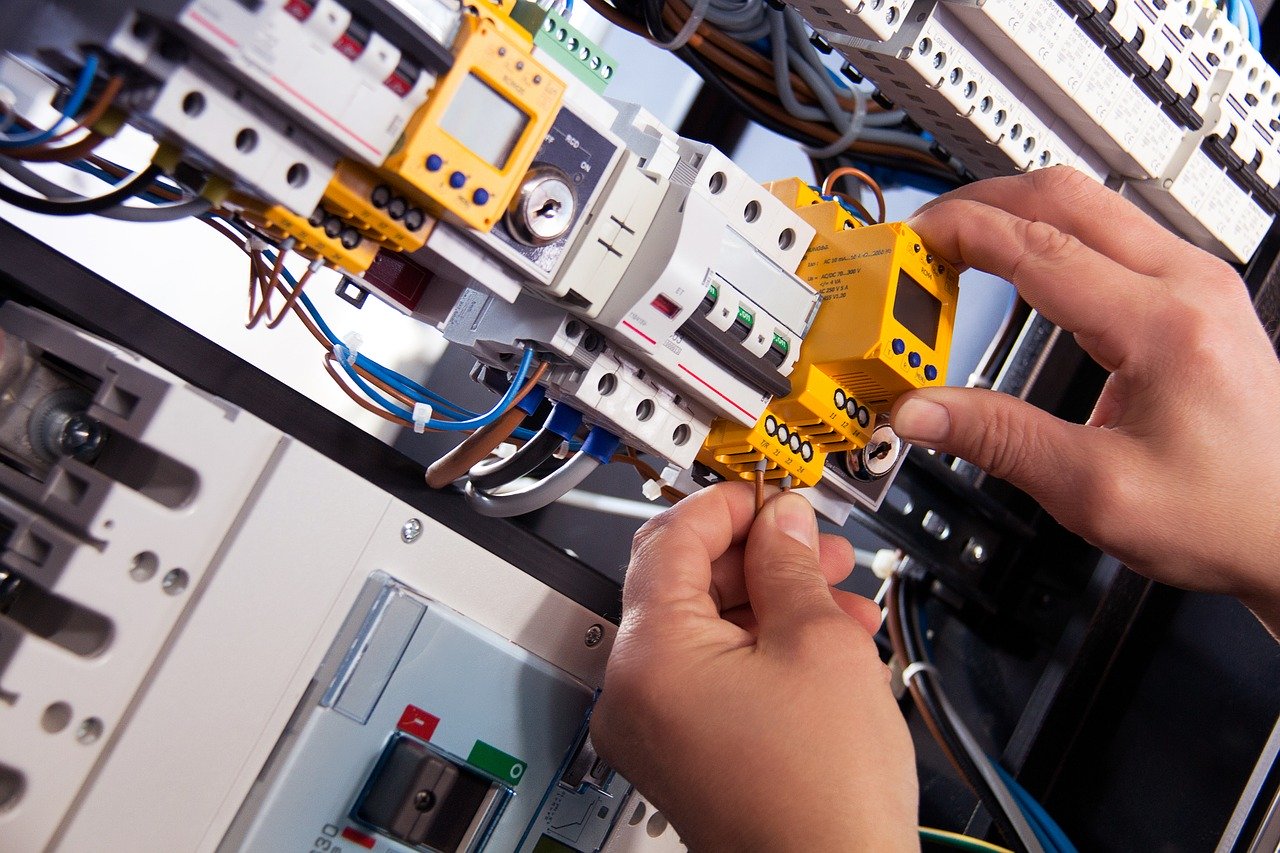

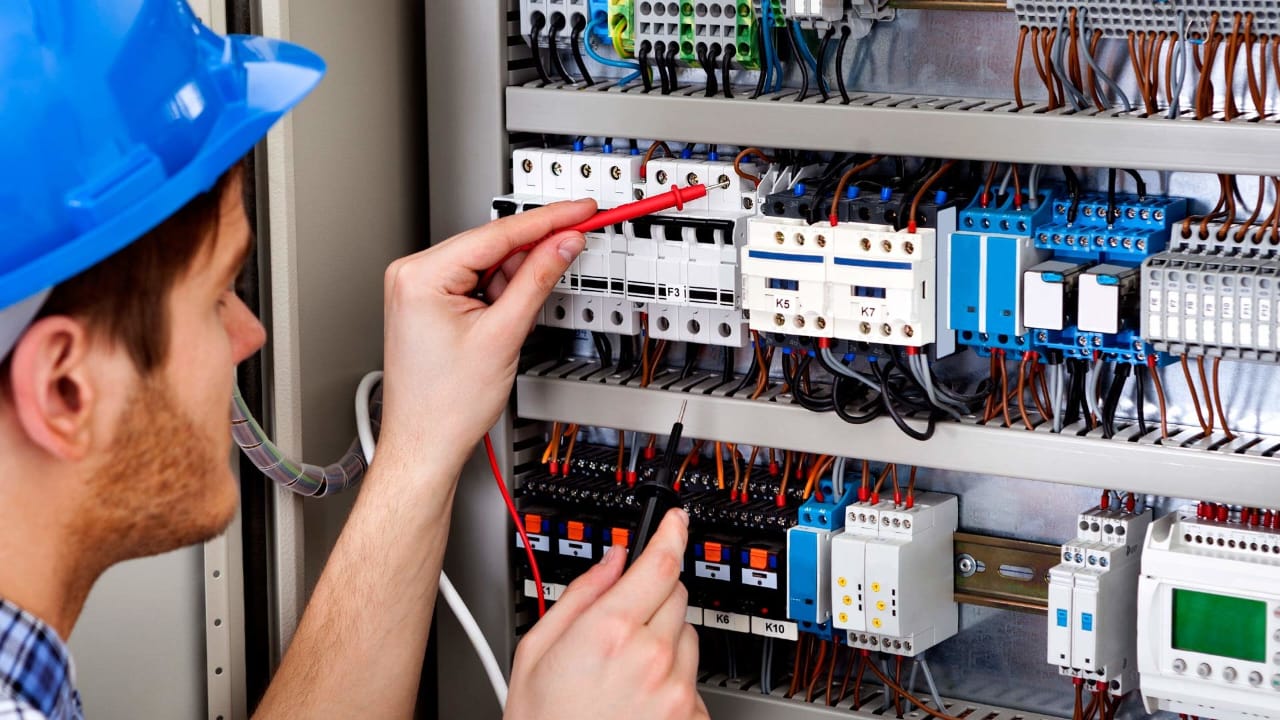

PLCs (Programmable Logic Controllers): Control and monitor machinery.

-

SCADA systems: Supervise and collect data from industrial processes.

-

Sensors & IoT devices: Provide real-time information about temperature, pressure, and performance.

-

AI & Machine Learning: Optimize production, detect patterns, and prevent failures.

Benefits of Industrial Automation

-

Higher Productivity: Machines work continuously with minimal downtime.

-

Consistent Quality: Automated systems reduce errors and defects.

-

Cost Efficiency: Lower labor costs and reduced waste.

-

Improved Safety: Hazardous tasks are handled by machines, protecting workers.

-

Data Insights: Real-time monitoring and analytics support better decision-making.

Types of Automation

-

Fixed Automation: Best for mass production (e.g., automotive assembly lines).

-

Programmable Automation: Flexible for batch production, with reprogramming options.

-

Flexible Automation: Can quickly adapt to product variations.

-

Integrated Automation: Entire production systems are digitally connected (Industry 4.0).

Modern Trends

-

Smart factories with interconnected machines.

-

Collaborative robots (cobots) working alongside humans.

-

Predictive maintenance using sensors to detect problems before breakdowns.

-

Sustainable automation to save energy and reduce waste.