Automation and Modernisation of Line Production Processes

In today’s competitive industrial environment, businesses must continuously improve efficiency, reduce costs, and maintain high product quality. One of the most effective ways to achieve this is through automation and modernisation of line production processes.

What is Line Production?

Line production (also called assembly line production) is a manufacturing method in which products move through a sequence of workstations, each performing a specific task, until the final product is complete. Traditionally, this process required significant manual labor.

Automation in Line Production

Automation introduces machines, robotics, sensors, and software systems to reduce manual intervention and improve productivity. Examples include:

-

Robotic arms for assembling, welding, or packaging.

-

Automated Guided Vehicles (AGVs) for material handling.

-

Conveyor systems with smart sensors to manage workflow.

-

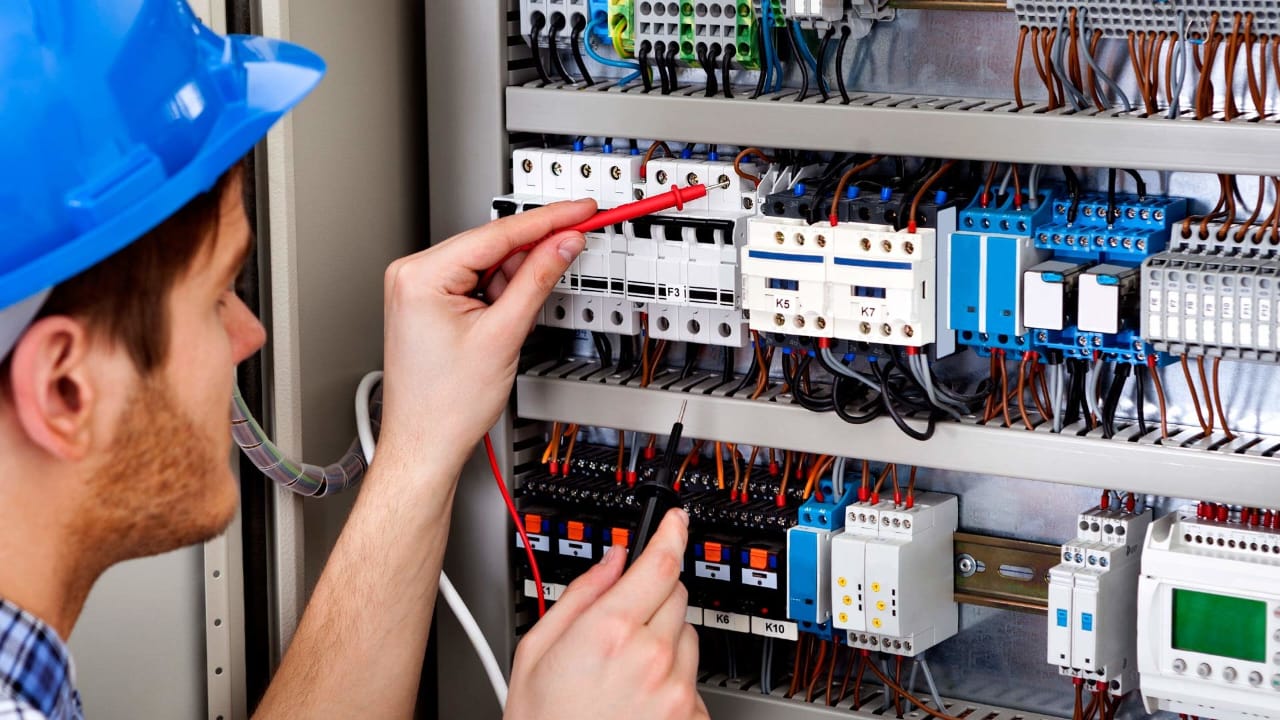

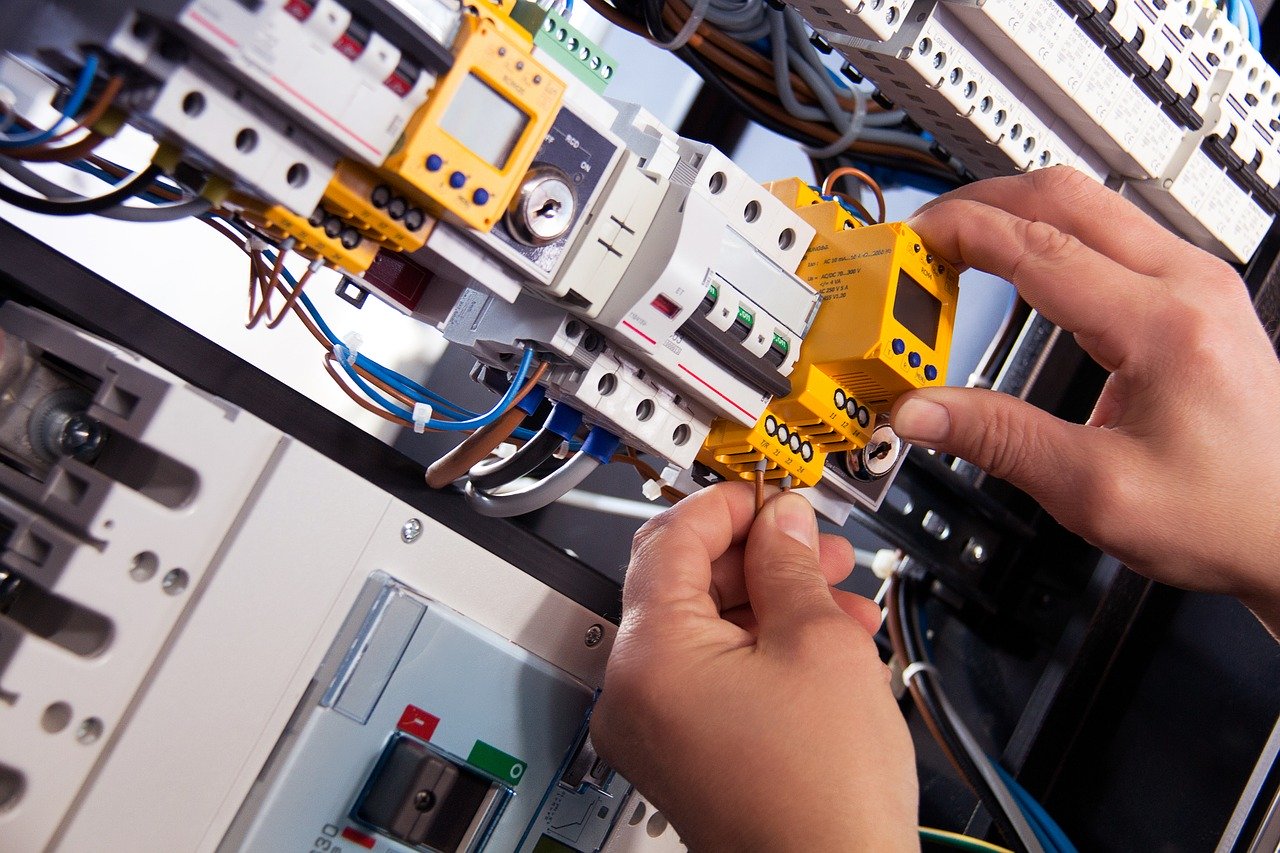

Programmable Logic Controllers (PLCs) to control and monitor processes.

-

AI-driven quality control systems using cameras and sensors to detect defects in real time.

Modernisation of Production Processes

Modernisation focuses on upgrading existing systems and integrating smart technologies:

-

Industrial Internet of Things (IIoT): Machines connected to share real-time performance data.

-

Smart sensors: Monitoring temperature, pressure, and machine conditions.

-

Data analytics: Predictive maintenance to avoid downtime.

-

Energy-efficient machinery: Reducing operating costs and environmental impact.

-

Flexible manufacturing systems (FMS): Adapting quickly to different product designs.

Benefits of Automation & Modernisation

-

Increased Efficiency – Faster production with reduced downtime.

-

Higher Quality – Consistent output and fewer defects.

-

Cost Reduction – Lower labor and maintenance costs in the long term.

-

Safety Improvement – Dangerous tasks handled by machines, reducing workplace accidents.

-

Scalability – Easier to ramp up production to meet market demand.

-

Sustainability – Modern systems consume less energy and reduce waste.

Example Applications

-

Automotive industry: Robotic welding, painting, and assembly.

-

Food and beverage: Automated filling, sealing, and packaging lines.

-

Pharmaceuticals: Precision dosing, labeling, and quality control.

-

Electronics: Automated PCB assembly and testing.